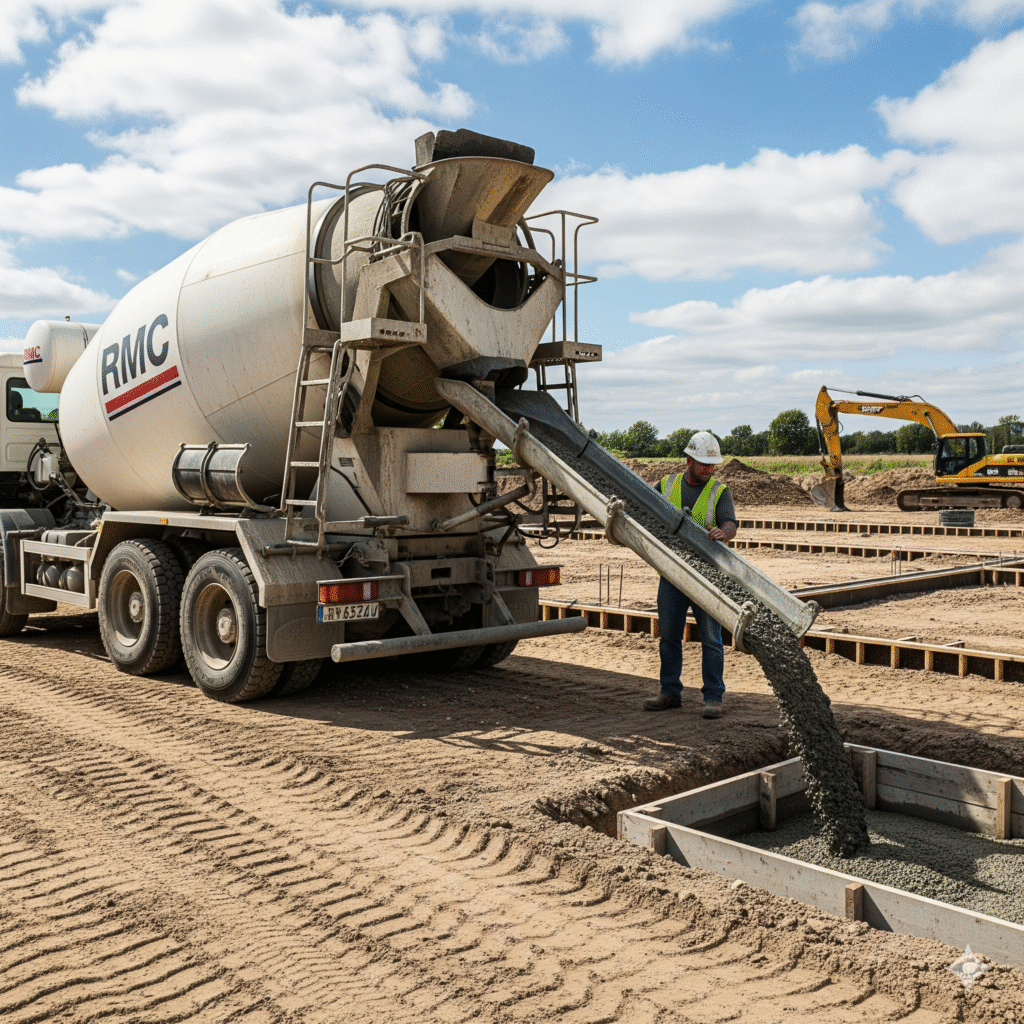

For builders, large-scale contractors, and property owners involved in modern construction, the critical decision of choosing between Ready-Mix Concrete (RMC) and traditional Site-Mixed Concreting is unavoidable. While site-mixing was once the default, RMC has rapidly become the prevalent choice across all classes of construction, from high-rise commercial towers to modern residential complexes in India.”

“What is the rationale driving this widespread popularity? It’s a shift rooted not just in convenience, but in structural science, efficiency, and economics. We will fundamentally dissect the differences between RMC and traditional mixing, exploring the key engineering advantages and long-term cost benefits that make Ready-Mix the clear choice for the future of construction.

The Science of Concreting: Providing Structural Strength

Concrete is a composite material, fundamentally a mix of Cement, Sand (Fine Aggregate), Coarse Aggregate, Admixtures, and water, combined in precise proportions. Upon hardening (curing), this mixture develops its essential strength.

The primary function of plain concrete is to provide Compressive Strength—its ability to resist forces that try to crush it. However, because concrete is inherently weak in resisting forces that try to pull it apart (Tensile Strength), TMT (Thermo-Mechanically Treated) steel bars are embedded within it. The combination of concrete (for compression) and TMT steel (for tension) forms Reinforced Cement Concrete (RCC).

Every structure is designed to withstand a specific design load, which is determined by the building’s purpose and local regulations. Based on this required load-bearing capacity, the necessary concrete strength is determined and specified using grades like M25, M30, M40, and so on. (The ‘M’ stands for mix, and the number denotes the minimum characteristic compressive strength of the concrete in Newtons per square millimeter ({N/mm}^2) after 28 days of curing). In order to consistently achieve the designed concrete strength (e.g., M30 or M40), Ready-Mix Concrete (RMC) relies on the Design Mix Principle.

This principle ensures that all ingredients—cement, sand, aggregates, water, and admixtures—are added in the correct, scientifically calculated proportions based on weight (weigh-batching). This process is executed by computerized batching plants that eliminate human error.

This high level of precision and uniformity is the foundational guarantee of RMC. It is the core reason RMC provides reliable, verifiable strength that often surpasses the quality of inconsistent, manually volumetric-batched site-mixed concrete.

In contrast, Traditional Site-Mixed Concreting typically relies on Volumetric Batching (or “thumb rule” methods) to proportion ingredients. This means the cement, sand, and aggregates are measured using approximate volumes (e.g., counting bags or using buckets) rather than precise weight.

This method introduces several critical flaws:

- Inexact Proportions: It is virtually impossible to maintain the correct, designed ratio of materials needed to achieve a specific concrete grade (like M30).

- Inconsistent Water-Cement Ratio: The most critical variable, water, is often added based on labor experience or visual feel to achieve desired workability, leading to batches with wildly inconsistent strength and durability.

- Vulnerability to Error: The entire process is highly dependent on the skill, focus, and honesty of the on-site labor, resulting in a variable and unreliable final product.

Ultimately, the lack of precision in site-mixing compromises the properties of the concrete, which can lead to structural weaknesses and long-term durability issues in the building.

🔬 RMC vs. Traditional Site-Mix Concreting: Comparative Analysis

| Feature | Ready-Mix Concrete (RMC) | Traditional Site-Mixed Concrete |

| Mixing Method | Automated Weigh-Batching (Computer-controlled and measured by weight). | Volumetric Batching (Manual measurement using buckets or ‘thumb rules’ by volume). |

| Consistency & Quality | Superior and Uniform. Precise {Water/Cement} ratio is maintained, guaranteeing the designed concrete grade (M25, M30, etc.). | Highly Variable. Prone to human error, resulting in fluctuating strength and quality between batches. |

| Material Wastage | Very Low. Exact quantity is batched and delivered, minimizing spillage and unutilized materials. | High. Significant wastage from inaccurate measurement, storage loss, and spillage during manual mixing. |

| Speed of Execution | Fastest. Arrives ready to pour, drastically reducing the time required for the casting stage. | Slow. Time is consumed by material handling, batching, mixing, and on-site testing. |

| Site Management | Clean. Eliminates the need to store raw materials (sand, cement, aggregates) on-site, reducing clutter, dust, and noise. | Cluttered. Requires large areas for raw material storage and generates high levels of dust and pollution. |

| Customization | High. Allows for lab-verified, specific admixtures (e.g., retarders, waterproofing, fiber-reinforcement) to be added precisely. | Limited. Admixtures are often added manually and inexactly, risking the integrity of the mix design. |

| Long-Term Durability | High. Guaranteed, consistent strength and reduced permeability lead to better long-term structural integrity. | Unreliable. Inconsistent mixing can lead to higher porosity and structural weaknesses over time. |

| Overall Cost | Higher Initial Cost per {m}^3. More cost-effective in the long run due to reduced labor, faster project completion, and minimal material wastage. | Lower Initial Cost. Higher hidden costs due to wastage, increased labor days, and potential rework due to inconsistent quality. |

💰 The Economics of RMC: Cost and Top Suppliers in India

While RMC offers technical superiority, the final decision often comes down to cost and trust in the supplier.

Average Cost of RMC in India

The cost of Ready-Mix Concrete (RMC) is highly variable and depends on the mix design, location, and volume ordered. The price is typically quoted per cubic meter ({m}^3).

| Factor | Estimated Average Price Range (Per m3) | Rationale |

| Standard Grade (M20/M25) | ₹3,500 – ₹4,500 | Suitable for residential slabs, foundations, and non-high-rise construction. |

| High Grade (M30/M40) | ₹4,500 – ₹5,500+ | Required for high-rise buildings, commercial structures, and high-strength concrete demands. |

| Specialized Mixes | ₹5,500 – ₹7,000+ | Includes mixes with special admixtures like waterproofing chemicals, fiber reinforcement, or high-performance additives. |

*prices may vary based on price of ingredients, geography, etc

Key Cost Drivers:

- Distance: The cost increases significantly if the batching plant is far from the construction site, due to increased fuel and transit mixer time.

- Admixtures: Adding specialized chemicals (e.g., retarders for slow setting in hot weather, plasticizers for higher workability) will increase the base price.

- Volume: Small orders typically have a higher unit cost, while large, continuous orders receive discounts.

The major cement manufacturers in India have integrated RMC facilities into their business models.

Key Players: These are the large national brands that offer widespread geographical coverage and strong quality assurance:

- UltraTech Concrete

- ACC Concrete

- RMC Ready Mix (India) (formerly Lafarge India) etc.

Alongside the national giants, there are numerous smaller, local RMC batching plants operating at the regional or city level.

🚚 Typical Capacity Range of transporting Mixers

In India and globally, transit mixers generally fall within the following volume range:

| Mixer Capacity (Volume) | Typical Use Case |

| Small | 4 to 6 cubic meters {m}^3 |

| Standard/Medium | 7 to 8 cubic meters {m}^3 |

| Large | 9 to 12 cubic meters {m}^3 |